Page 120 -

P. 120

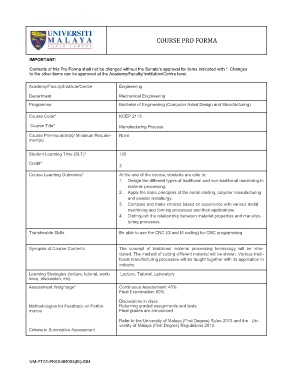

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Institute/Centre Engineering

Department Mechanical Engineering

Programme Bachelor of Engineering (Computer Aided Design and Manufacturing)

Course Code* KCEP 2113

Course Title* Manufacturing Process

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120

Credit*

3

Course Learning Outcomes* At the end of the course, students are able to:

1. Design the different types of traditional and non-traditional machining in

material processing.

2. Apply the basic principles of the metal casting, polymer manufacturing

and powder metallurgy.

3. Compare and make choices based on experience with various metal

machining and forming processes and their applications

4. Distinguish the relationship between material properties and manufac-

turing processes.

Transferable Skills Be able to use the CNC (G and M coding) for CNC programming

Synopsis of Course Contents The concept of traditional material processing technology will be intro-

duced. The method of cutting different material will be shown. Various tradi-

tional manufacturing processes will be taught together with its application in

industry.

Learning Strategies (lecture, tutorial, work- Lecture, Tutorial, Laboratory

shop, discussion, etc)

Assessment Weightage* Continuous Assessment: 40%

Final Examination: 60%

Discussions in class

Methodologies for Feedback on Perfor- Returning graded assignments and tests

mance Final grades are announced

Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

Criteria in Summative Assessment

UM-PT01-PK03-BR003(BI)-S04