Page 157 -

P. 157

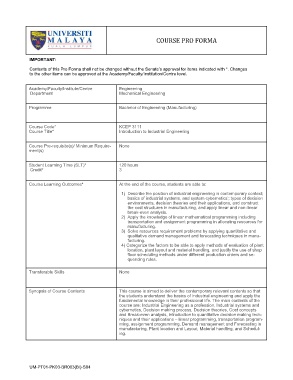

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Institute/Centre Engineering

Department Mechanical Engineering

Programme Bachelor of Engineering (Manufacturing)

Course Code* KCEP 3111

Course Title* Introduction to Industrial Engineering

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120 hours

Credit* 3

Course Learning Outcomes* At the end of the course, students are able to:

1) Describe the position of industrial engineering in contemporary context;

basics of industrial systems, and system cybernetics’; types of decision

environments, decision theories and their applications, and construct

the cost structures in manufacturing, and apply linear and non-linear

break-even analysis.

2) Apply the knowledge of linear mathematical programming including

transportation and assignment programming in allocating resources for

manufacturing.

3) Solve resources requirement problems by applying quantitative and

qualitative demand management and forecasting techniques in manu-

facturing.

4) Categorize the factors to be able to apply methods of evaluation of plant

location, plant layout and material handling, and justify the use of shop

floor scheduling methods under different production orders and se-

quencing rules.

Transferable Skills None

Synopsis of Course Contents This course is aimed to deliver the contemporary relevant contents so that

the students understand the basics of Industrial engineering and apply the

fundamental knowledge in their professional life. The main contents of the

course are: Industrial Engineering as a profession, Industrial systems and

cybernetics, Decision making process, Decision theories, Cost concepts

and Break-even analysis, introduction to quantitative decision making tech-

niques and their applications – linear programming, transportation program-

ming, assignment programming, Demand management and Forecasting in

manufacturing, Plant location and Layout, Material handling, and Schedul-

ing.

UM-PT01-PK03-BR003(BI)-S04