Page 166 -

P. 166

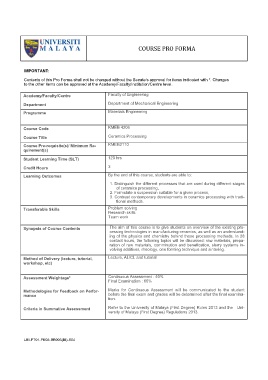

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Centre Faculty of Engineering

Department Department of Mechanical Engineering

Programme Materials Engineering

Course Code KMEB 4206

Course Title Ceramics Processing

Course Pre-requisite(s)/ Minimum Re- KMEB2110

quirement(s)

Student Learning Time (SLT) 120 hrs

Credit Hours 3

Learning Outcomes By the end of this course, students are able to:

1. Distinguish the different processes that are used during different stages

of ceramics processing,

2. Formulate a suspension suitable for a given process,

3. Contrast contemporary developments in ceramics processing with tradi-

tional methods.

Transferable Skills Problem solving

Research skills

Team work

Synopsis of Course Contents The aim of this course is to give students on overview of the existing pro-

cessing technologies in manufacturing ceramics, as well as an understand-

ing of the physics and chemistry behind those processing methods. In 28

contact hours, the following topics will be discussed: raw materials, prepa-

ration of raw materials, comminution and benefication, slurry systems in-

volving additives, rheology, one forming technique and sintering.

Method of Delivery (lecture, tutorial, Lecture, AL/CL and tutorial

workshop, etc)

Assessment Weightage* Continuous Assessment : 40%

Final Examination : 60%

Methodologies for Feedback on Perfor- Marks for Continuous Assessment will be communicated to the student

mance before the final exam and grades will be determined after the final examina-

tion.

Criteria in Summative Assessment Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

UM-PT01-PK03-BR003(BI)-S04