Page 190 -

P. 190

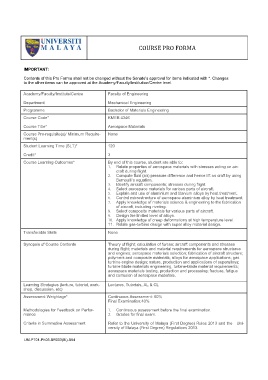

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Institute/Centre Faculty of Engineering

Department Mechanical Engineering

Programme Bachelor of Materials Engineering

Course Code* KMEB 4346

Course Title* Aerospace Materials

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120

Credit* 3

Course Learning Outcomes* By end of this course, student are able to:

1. Relate properties of aerospace materials with stresses acting on air-

craft during flight.

2. Compute fluid (air) pressure difference and hence lift on craft by using

Bernoulli’s equation.

3. Identify aircraft components; stresses during flight.

4. Select aerospace materials for various parts of aircraft.

5. Explain and use of aluminium and titanium alloys by heat treatment.

6. Control microstructure of aerospace aluminium alloy by heat treatment.

7. Apply knowledge of materials science & engineering to the fabrication

of aircraft, including riveting.

8. Select composite materials for various parts of aircraft.

9. Design the limited level of alloys.

10. Apply knowledge of creep deformations at high temperature level.

11. Relate gas-turbine design with super alloy material design.

Transferable Skills None

Synopsis of Course Contents Theory of flight; calculation of forces; aircraft components and stresses

during flight; materials and material requirements for aerospace structures

and engines; aerospace materials selection; fabrication of aircraft structure;

polymers and composite materials; alloys for aerospace applications; gas

turbine engine design; nature, production and applications of superalloys;

turbine blade materials engineering, turbine-blade material requirements;

aerospace materials testing, production and processing; fracture, fatigue

and corrosion of aerospace materials.

Learning Strategies (lecture, tutorial, work- Lectures, Tutorials, AL & CL

shop, discussion, etc)

Assessment Weightage* Continuous Assessment: 60%

Final Examination:40%

Methodologies for Feedback on Perfor- 1. Continuous assessment before the final examination.

mance 2. Grades for final exam.

Criteria in Summative Assessment Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

UM-PT01-PK03-BR003(BI)-S04