Page 135 -

P. 135

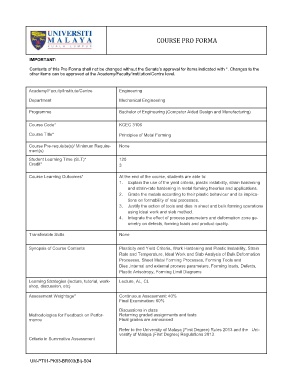

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes to the

other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Institute/Centre Engineering

Department Mechanical Engineering

Programme Bachelor of Engineering (Computer Aided Design and Manufacturing)

Course Code* KCEC 3106

Course Title* Principles of Metal Forming

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120

Credit* 3

Course Learning Outcomes* At the end of the course, students are able to:

1. Explain the use of the yield criteria, plastic instability, strain hardening

and strain-rate hardening in metal forming theories and applications.

2. Grade the metals according to their plastic behaviour and its implica-

tions on formability of real processes.

3. Justify the action of tools and dies in sheet and bulk forming operations

using ideal work and slab method.

4. Integrate the effect of process parameters and deformation zone ge-

ometry on defects, forming loads and product quality.

Transferable Skills None

Synopsis of Course Contents Plasticity and Yield Criteria, Work Hardening and Plastic Instability, Strain

Rate and Temperature, Ideal Work and Slab Analysis of Bulk Deformation

Processes, Sheet Metal Forming Processes, Forming Tools and

Dies ,internal and external process parameters, Forming loads, Defects,

Plastic Anisotropy, Forming Limit Diagrams

Learning Strategies (lecture, tutorial, work- Lecture, AL, CL

shop, discussion, etc)

Assessment Weightage* Continuous Assessment: 40%

Final Examination: 60%

Discussions in class

Methodologies for Feedback on Perfor- Returning graded assignments and tests

mance Final grades are announced

Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

Criteria in Summative Assessment

UM-PT01-PK03-BR003(BI)-S04