Page 156 -

P. 156

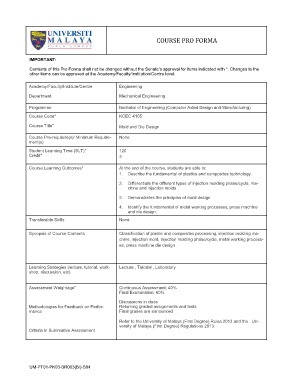

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes to the

other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Institute/Centre Engineering

Department Mechanical Engineering

Programme Bachelor of Engineering (Computer Aided Design and Manufacturing)

Course Code* KCEC 4105

Course Title* Mold and Die Design

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120

Credit* 3

Course Learning Outcomes* At the end of the course, students are able to:

1. Describe the fundamental of plastics and composites technology.

2. Differentiate the different types of injection molding phase/cycle, ma-

chine and injection molds

3. Demonstrates the principles of mold design

4. Identify the fundamental of metal working processes, press machine

and die design.

Transferable Skills None

Synopsis of Course Contents Classification of plastic and composites processing, injection molding ma-

chine, injection mold, injection molding phase/cycle, metal working process-

es, press machine die design

Learning Strategies (lecture, tutorial, work- Lecture , Tutorial , Laboratory

shop, discussion, etc)

Assessment Weightage* Continuous Assessment: 40%

Final Examination: 60%

Discussions in class

Methodologies for Feedback on Perfor- Returning graded assignments and tests

mance Final grades are announced

Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

Criteria in Summative Assessment

UM-PT01-PK03-BR003(BI)-S04