Page 96 -

P. 96

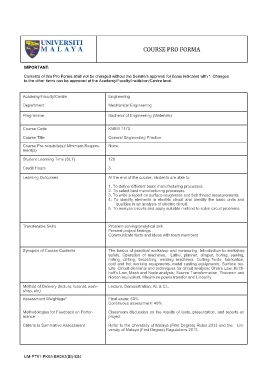

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Centre Engineering

Department Mechanical Engineering

Programme Bachelor of Engineering (Materials)

Course Code KMEB 1170

Course Title General Engineering Practice

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT) 120

Credit Hours 3

Learning Outcomes At the end of the course, students are able to:

1. To define different basic manufacturing processes.

2. To select best manufacturing processes

3. To write a report on surface roughness and bolt thread measurements

4. To identify elements in electric circuit and identify the basic units and

qualities in an analysis of electric circuit.

5. To analyze circuits and apply suitable method to solve circuit problems.

Transferable Skills Problem solving/analytical skill

Present project findings

Communicate facts and ideas with team members

Synopsis of Course Contents The basics of practical workshop and measuring. Introduction to workshop

safety. Operation of machines. Lathe, planner, shaper, boring, sawing,

milling, drilling, broaching, welding machines. Cutting fluids, lubrication,

cold and hot working equipments, metal casting equipments, Surface tex-

ture. Circuit elements and techniques for circuit analysis; Ohm’s Law, Kirch-

hoff’s Law, Mesh and Node analysis, Source Transformation, Thevenin and

Norton equivalent, Maximum power transfer and Linearity.

Method of Delivery (lecture, tutorial, work- Lecture, Demonstration, AL & CL.

shop, etc)

Assessment Weightage* Final exam: 60%

Continuous assessment: 40%

Methodologies for Feedback on Perfor- Classroom discussion on the results of tests, presentation, and reports on

mance project

Criteria in Summative Assessment Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

UM-PT01-PK03-BR003(BI)-S04