Page 199 -

P. 199

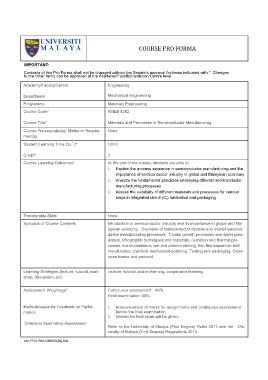

COURSE PRO FORMA

IMPORTANT:

Contents of this Pro Forma shall not be changed without the Senate’s approval for items indicated with *. Changes

to the other items can be approved at the Academy/Faculty/Institution/Centre level.

Academy/Faculty/Centre Engineering

Department Mechanical Engineering

Programme Materials Engineering

Course Code* KMEB 4352

Course Title* Materials and Processes in Semiconductor Manufacturing

Course Pre-requisite(s)/ Minimum Require- None

ment(s)

Student Learning Time (SLT)* 120 h

Credit* 3

Course Learning Outcomes* At the end of the course, students are able to:

1. Explain the process sequence in semiconductor manufacturing and the

importance of semiconductor industry in global and Malaysian economy

2. Analyze the fundamental principles underlying different semiconductor

manufacturing processes

3. Assess the suitability of different materials and processes for various

steps in integrated circuit (IC) fabrication and packaging

Transferable Skills None

Synopsis of Course Contents Introduction to semiconductor industry and its importance in global and Ma-

laysian economy. Overview of semiconductor devices and overall semicon-

ductor manufacturing processes. Crystal growth processes and wafer prep-

aration, lithographic techniques and materials, oxidation and thermal pro-

cesses, ion implantation, wet and plasma etching, thin film deposition and

metallization, chemical mechanical polishing. Testing and packaging. Clean

room basics and protocol.

Learning Strategies (lecture, tutorial, work- Lecture, tutorial, active learning, cooperative learning

shop, discussion, etc)

Assessment Weightage* Continuous assessment : 40%

Final examination: 60%

Methodologies for Feedback on Perfor- 1. Announcement of marks for assignments and continuous assessment

mance before the final examination.

2. Grades for final exam will be given.

Criteria in Summative Assessment

Refer to the University of Malaya (First Degree) Rules 2013 and the Uni-

versity of Malaya (First Degree) Regulations 2013.

UM-PT01-PK03-BR003(BI)-S04